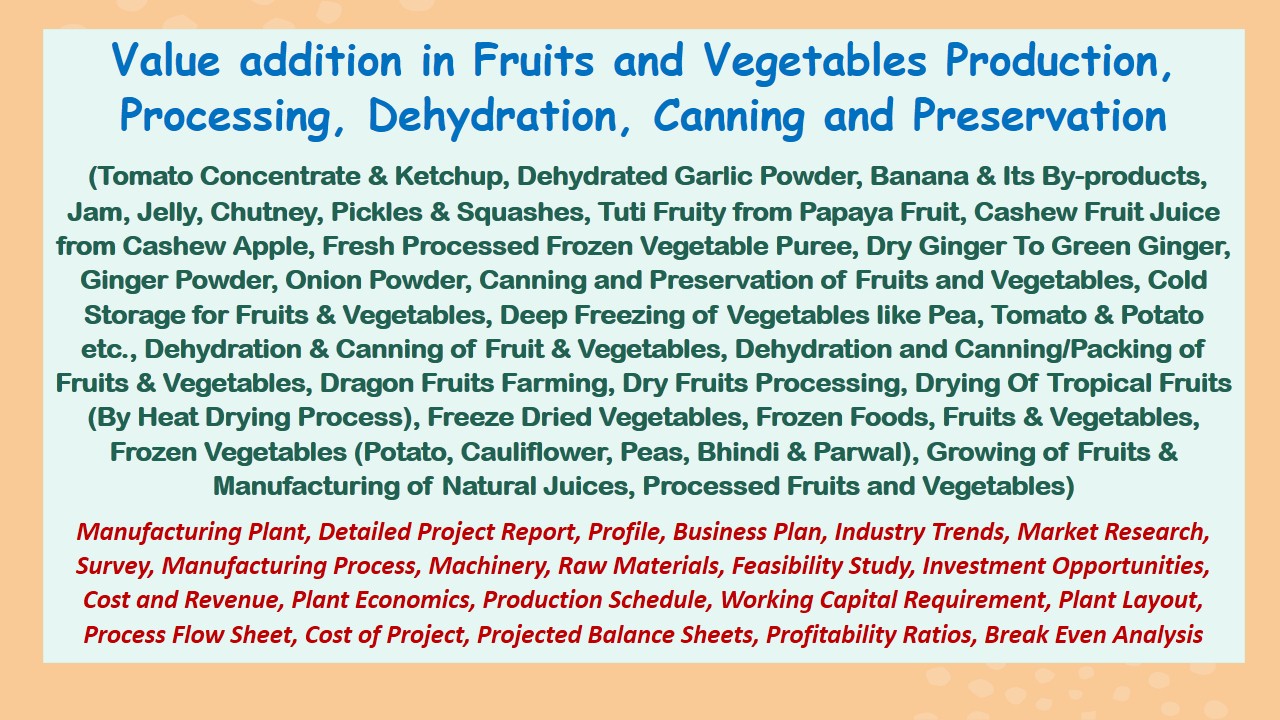

Value addition in Fruits & Vegetables is a transformative process that turns perishable produce into shelf-stable, profitable products. Through methods such as dehydration, pickling, canning, and processing into items like banana chips, garlic powder, jams, and sauces, fresh produce can be preserved, enhanced, and made available year-round. This not only reduces post-harvest losses but also opens up new market opportunities for farmers, entrepreneurs, and food manufacturers. Moreover, the demand for convenient, healthy, and ready-to-use foods is rising rapidly, both locally and globally. In this guide, we explore various value-added processes, the range of products that can be made, and how to build a sustainable business around Fruits & Vegetables processing.

Unlocking the Potential of Value Addition in Fruits & Vegetables

Value addition involves enhancing the economic value of agricultural produce by changing its form, improving its shelf life, and meeting consumer preferences. For Fruits & Vegetables, this could mean converting them into dehydrated snacks, purees, sauces, or fermented items. These products not only retain nutrition but often fetch much higher prices than raw produce.

The process typically includes cleaning, peeling, cutting, drying or cooking, packaging, and labeling. Small and medium enterprises (SMEs), farmer-producer organizations (FPOs), and startups all play vital roles in developing this segment. Let’s explore key product categories and processing methods.

See More : NPK Fertilizer Plant

Dehydrated Fruits & Vegetables

Dehydration is one of the oldest and most cost-effective forms of food preservation. It removes moisture from produce to inhibit microbial growth and spoilage.

Fruits like mango, banana, papaya, and apple are sliced and sun-dried or dehydrated using hot air ovens. Similarly, vegetables like onions, tomatoes, garlic, and carrots are dried into flakes or powders.

These dried products are used in cooking, snack manufacturing, seasoning blends, and even instant food kits. For example, garlic powder, onion flakes, and tomato powder have significant commercial value in domestic and export markets.

Moreover, dehydration requires minimal packaging and logistics, making it ideal for rural micro-enterprises.

Banana Chips & Fruit Snacks

Banana chips are among the most popular processed fruit snacks globally. Raw bananas are peeled, thinly sliced, and deep-fried or vacuum-fried, then seasoned with salt or spices. They are then packed in nitrogen-flushed pouches to retain freshness.

Fruit bars and slices from mangoes, jackfruit, pineapple, and guava also have strong demand. These snacks are often sold as healthy alternatives to sugary confectionery and appeal to health-conscious consumers.

Moreover, value-added snacks like these allow farmers to utilize overripe or unsellable fruits effectively, turning potential waste into profit.

Tomato Ketchup, Purees & Sauces

Processing tomatoes into ketchup, puree, and sauces adds significant value to this highly perishable vegetable. Fresh tomatoes are washed, pulped, filtered, and cooked with sugar, salt, vinegar, and spices to make ketchup. The product is then pasteurized and packed into bottles or sachets.

Tomato puree and sauces have consistent demand in households, hotels, and restaurants. With increasing fast food consumption, processed tomato products are essential components in pizzas, pastas, and curries.

Additionally, regional variants such as spicy tomato chutneys or garlic-tomato sauces cater to diverse taste profiles and are ideal for local markets.

Jams, Jellies & Fruit Preserves

Jams and jellies are sweetened fruit-based products made by boiling fruit pulp with sugar and pectin until a thick consistency is achieved. Fruits like strawberry, guava, mixed berries, mango, and apricot are commonly used.

These spreads are packed in glass jars or food-grade plastic tubs and enjoy strong demand across urban and rural markets. In contrast to imported spreads, locally made jams often contain higher fruit content and cater to regional flavor preferences.

Moreover, these products serve as an excellent entry point for small-scale processors, especially women-led businesses and FPOs.

Pickles, Chutneys & Fermented Products

Traditional pickles and chutneys made from fruits and vegetables such as mango, lemon, carrot, chili, or gooseberry (amla) offer high margins and long shelf life. These are prepared using salt, oil, and spices to preserve flavor and inhibit microbial growth.

Fermented products like kimchi, sauerkraut, and fruit vinegar are gaining popularity for their probiotic benefits. Such items not only offer health advantages but also appeal to modern, wellness-oriented consumers.

As a result, pickles and fermented products represent a fusion of cultural heritage and modern food trends—making them ideal for both domestic consumption and niche exports.

Vegetable Purees & Ready-to-Eat Gravies

Vegetables like spinach, peas, carrots, and pumpkin are commonly processed into purees for baby food or industrial use. These purees are pasteurized and aseptically packed for long-term storage.

In the ready-to-eat (RTE) segment, vegetable-based gravies, curry bases, and meal kits are gaining popularity. These products are heat-treated and packed in retort pouches to ensure shelf stability without refrigeration.

Moreover, these convenience products save time for consumers and chefs alike, creating strong retail and institutional demand.

Canned Fruits & Vegetables

Canning involves sealing food in airtight containers and heat-sterilizing them to destroy microbes. Common canned items include pineapples, lychees, peaches, mushrooms, sweet corn, and mixed vegetables.

Canned goods are popular in both domestic and export markets. They offer long shelf life (up to 2–3 years), ease of storage, and consistent quality. As a result, canned fruits and vegetables form an essential part of the global processed food trade.

However, this segment requires significant investment in machinery and strict quality controls to ensure food safety.

Business Opportunities in Value Addition

Processing Fruits & Vegetables opens up various scalable business models:

-

Home-scale operations: Ideal for pickles, jams, and fruit snacks

-

Cottage industries: For chutneys, sun-dried fruits, and powders

-

SMEs: For ketchup, sauces, canned goods, and RTE foods

-

Export-focused units: For dehydrated, freeze-dried, and organic products

-

Private-label manufacturing: Partner with retailers or D2C brands

With increasing demand for clean-label, preservative-free, and healthy snacks, there’s a growing market for natural and artisanal fruit and vegetable products.

Sourcing, Seasonality & Supply Chain

The success of any value-added enterprise begins with quality sourcing. It’s important to select ripe, undamaged, and pesticide-free produce. While some processors own farms or greenhouses, others procure through farmer contracts or wholesale markets.

Seasonality can affect availability and pricing. Therefore, techniques like cold storage, dehydration, or pureeing during the harvest peak help stabilize inventory for year-round production.

Moreover, working with farmer cooperatives ensures steady supply, better pricing, and higher rural incomes.

Packaging, Branding & Market Access

Attractive and functional packaging is critical to ensure product safety and attract consumers. Packaging formats include:

-

Glass jars (jams, pickles, chutneys)

-

Vacuum-sealed pouches (banana chips, powders)

-

PET bottles (ketchup, sauces)

-

Retort pouches (RTE gravies)

Modern consumers also expect recyclable or biodegradable packaging, which can be a strong branding element.

For market access, value-added products can be sold through:

-

Local grocery stores and supermarkets

-

Online platforms and D2C websites

-

Exhibitions, farmer markets, and food expos

-

Export channels via distributors or e-commerce

A strong brand story around freshness, sustainability, or tradition can greatly increase product appeal.

Government Support & Quality Standards

Many governments promote value addition through subsidies, grants, and training programs. In India, schemes like PMFME, MIDH, and APEDA support processing units, especially those run by women and FPOs.

Compliance with food safety standards is essential. These include FSSAI (India), FDA (USA), EU regulations, and others. Good Manufacturing Practices (GMP), HACCP certification, and proper labelling ensure customer trust and legal compliance.

In addition, incubators and food parks provide shared infrastructure and mentoring for startups entering the value addition space.

Conclusion

Processing Fruits & Vegetables into value-added products offers immense economic and social benefits. It enhances shelf life, reduces post-harvest losses, increases farmer income, and meets the growing consumer demand for convenient, healthy food options. Whether it’s banana chips, tomato ketchup, garlic powder, jams, or chutneys, each processed item represents an opportunity to innovate and earn. With access to the right raw materials, equipment, market insights, and quality controls, entrepreneurs can turn simple produce into powerful food brands. The future of food lies not just in growing more—but in adding more value to what we grow.