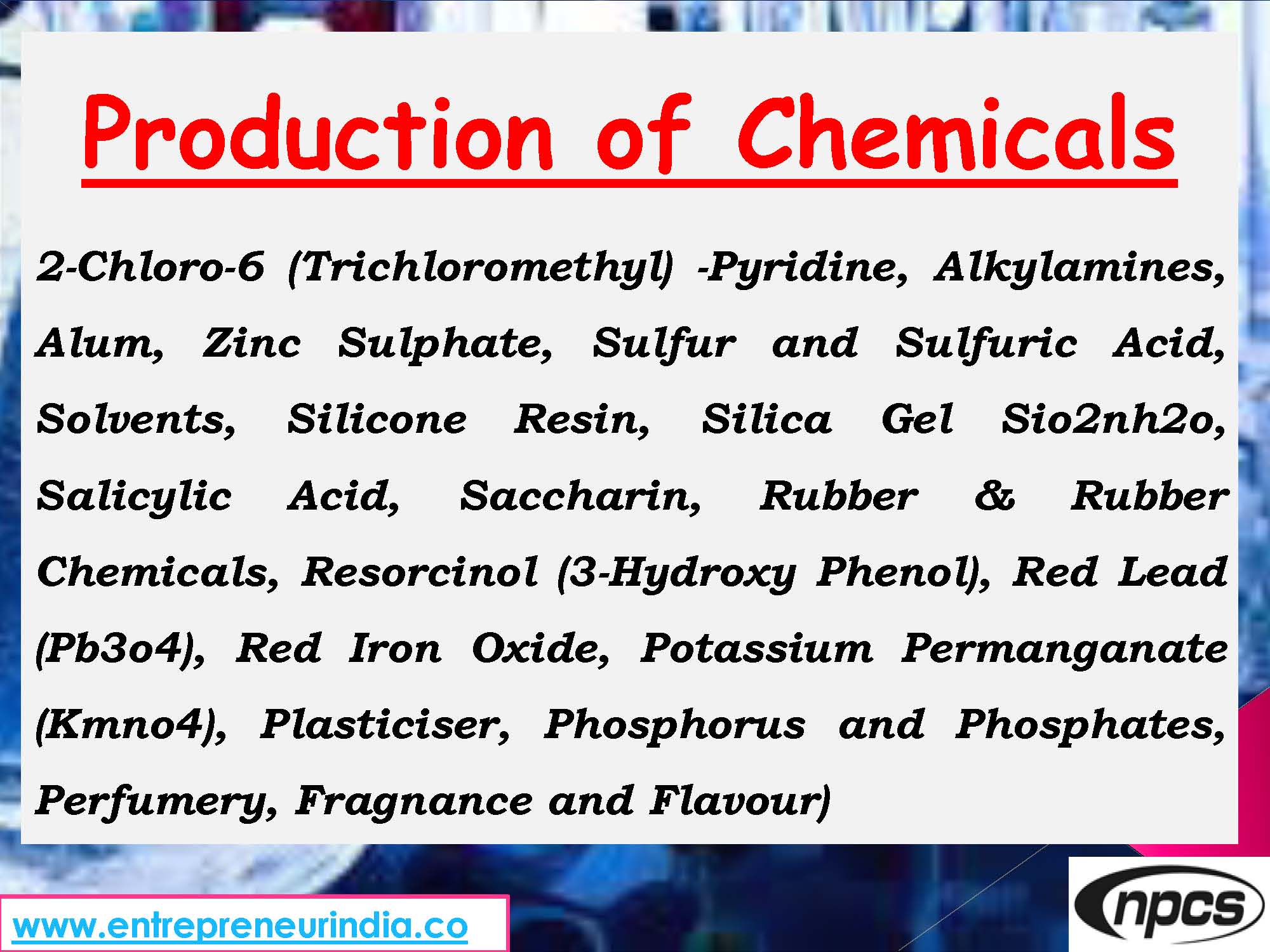

The chemical industry plays a vital role in shaping the global economy through the manufacturing of essential compounds used across pharmaceuticals, agriculture, construction, and daily-use products. From intermediates like 2-chloro-6-trichloromethyl-pyridine to bulk chemicals such as sulfuric acid and zinc sulphate, the demand for high-quality chemical production continues to rise. The keyword production-of-chemicals-2-chloro-6-trichloromethyl-pyridine-alkylamines-alum-zinc-sulphate-sulfur-and-sulfuric-acid-solvents-silicone-resin-silica-gel-sio2nh2o-salicylic-acid-saccharin-r encompasses a wide range of chemical substances, each requiring specific processes, raw materials, and quality control measures. Moreover, the industry is evolving with greener technologies and improved safety standards, making chemical manufacturing more efficient and environmentally responsible.

Key Chemical Compounds and Their Industrial Production

Chemical manufacturing is a complex but systematic process involving raw material selection, controlled reactions, purification, and product formulation. Below we explore major compounds listed in the keyword, focusing on their production methods, industrial applications, and handling precautions. The production-of-chemicals-2-chloro-6-trichloromethyl-pyridine-alkylamines-alum-zinc-sulphate-sulfur-and-sulfuric-acid-solvents-silicone-resin-silica-gel-sio2nh2o-salicylic-acid-saccharin-r contributes significantly to pharmaceuticals, agriculture, and consumer goods.

Read More :Agriculture & Food

2-Chloro-6-Trichloromethyl Pyridine: Herbicide Intermediate

This compound is a critical intermediate in herbicide synthesis, particularly for the manufacture of chlorpyrifos and other organophosphates. Its production involves chlorination of 2-chloropyridine under controlled conditions using chlorinating agents such as phosphorus pentachloride. Due to its reactivity and potential toxicity, stringent measures are applied during synthesis and storage. Moreover, it’s typically used in closed systems to prevent occupational exposure and environmental contamination.

Alkylamines: Key Building Blocks

Alkylamines, including methylamine, ethylamine, and isopropylamine, are produced by the amination of alcohols using ammonia under high pressure and catalysis. These chemicals serve as vital intermediates in pharmaceuticals, rubber processing, agrochemicals, and surfactants. Production processes vary based on desired chain length and substitution. For instance, monoalkylamines require precise temperature and catalyst control to prevent multiple alkylations. Their versatile nature ensures they are foundational in modern chemical engineering.

Alum and Zinc Sulphate: Inorganic Compounds for Water Treatment

Alum (aluminium potassium sulfate) is produced by treating bauxite with sulfuric acid, followed by crystallization. It is widely used in water purification, paper sizing, and as a mordant in dyeing. Similarly, zinc sulphate is prepared through the reaction of zinc oxide or zinc ash with sulfuric acid. Both compounds play a crucial role in agriculture (as micronutrients) and industrial water treatment. Moreover, their non-toxic profile and broad usability make them indispensable to sustainable industrial operations.

Sulfur and Sulfuric Acid: Bulk Industrial Chemicals

Sulfur is primarily obtained via the Frasch process or as a byproduct of petroleum refining. It is then oxidized to produce sulfur dioxide, which is further converted to sulfur trioxide and finally sulfuric acid through the Contact Process. Sulfuric acid is one of the most produced chemicals globally, used in fertilizers, batteries, detergents, and chemical synthesis. Its corrosive nature demands careful material selection for piping and storage. As a result, it is often handled in corrosion-resistant containers under strict regulations.

Solvents and Silicone Resin: Versatile Industrial Agents

Common organic solvents such as acetone, toluene, and ethanol are typically derived from petroleum refining or fermentation. They are crucial for dissolution, extraction, and chemical reactions across many industries. Meanwhile, silicone resin is produced by hydrolysis and condensation of organosilicon compounds. It exhibits exceptional heat resistance, electrical insulation, and weather durability, making it suitable for coatings, electronics, and sealants. These materials highlight the diversity in applications under the umbrella of production-of-chemicals-2-chloro-6-trichloromethyl-pyridine-alkylamines-alum-zinc-sulphate-sulfur-and-sulfuric-acid-solvents-silicone-resin-silica-gel-sio2nh2o-salicylic-acid-saccharin-r.

Silica Gel (SiO?·nH?O): Desiccant and Catalyst Support

Silica gel is synthesized by acidifying sodium silicate, which precipitates hydrated silicon dioxide. The resulting gel is then dried to achieve the desired pore structure. It serves as an efficient moisture absorber, chromatography medium, and catalyst support. Non-toxic and chemically stable, it is commonly found in pharmaceutical packaging, electronics, and laboratories. Its porosity can be tailored for specific industrial or scientific requirements, making it a highly adaptable material.

Salicylic Acid and Saccharin: Pharmaceuticals and Sweeteners

Salicylic acid, produced via the Kolbe–Schmitt reaction, is a precursor in aspirin and widely used in skincare for its keratolytic and anti-inflammatory properties. In contrast, saccharin, an artificial sweetener, is synthesized from toluene derivatives and sulfur dioxide. Despite past controversy, saccharin remains FDA-approved and is used in diet beverages and diabetic-friendly foods. These compounds represent how chemical production intersects with consumer health and well-being, driven by innovation and regulatory compliance.

See Also : Beverage & Food

Conclusion

The vast scope of production-of-chemicals-2-chloro-6-trichloromethyl-pyridine-alkylamines-alum-zinc-sulphate-sulfur-and-sulfuric-acid-solvents-silicone-resin-silica-gel-sio2nh2o-salicylic-acid-saccharin-r reflects the backbone of modern industry. From fertilizers to pharmaceuticals, each compound serves a unique purpose in enhancing human life and economic output. Moreover, the integration of safer technologies, green chemistry, and process optimization is transforming chemical manufacturing into a more responsible and efficient sector. As demand rises, so does the importance of stringent quality control and sustainable practices in chemical production worldwide.