In India’s growing economy, cold storage plays a vital role in reducing food wastage, maintaining the integrity of pharmaceuticals, and enabling timely deliveries for e-commerce. From milk produced in rural dairy farms to vaccines shipped from pharmaceutical hubs to frozen food catering to urban populations, cold chain infrastructure is a need of the hour. In this article, we will explore the business potential, necessary technical setup, market relevance, and legal considerations involved in operating a cold storage business.

The Importance of Cold Storage in Today’s India

India generates more than 300 million metric tons of perishable food every year. Unfortunately, almost 30–40% of this food is wasted due to the lack of cold chain systems. This situation is detrimental not only to the farmers and food prices, but is a huge loss to food security. In addition to this, the rising demand for pharmaceuticals, frozen food, and e-grocery services is further increasing the need for controlled climate storage. The scope of cold storage now extends beyond rural supply chains. Today, it is an integral part of a myriad of sectors such as agriculture, seafood, pharmaceuticals, and fast-moving consumer goods.

Related: How to Start a Profitable Cold Storage Business

Key Aspects of Cold Storage Storage Units

A sufficient cold storage environment, controlling temperature and weather conditions, along with an efficient cooling system forms the basis of the operations in cold storage facilities. The systems ensure that there is no spoilage, bacterial growth, or damage to the products due to changes in temperature. Temperature and humidity regulation, along with efficient circulation and stacking, is crucial in advanced facilities. Additionally, the advanced facilities incorporate enhanced real time tracking systems that boosts energy and inventory management.

Classification Of Cold Storage

According to a Cold Storage Facilities India, there are three primary classifications. Private cold storage are owned by organizations such as food processors and pharmaceutical manufacturers for in-house use. Public or third-party storage are owned by third parties that rent the storage spaces to traders, exporters, and wholesalers. Emerging as a versatile option, flexible or hybrid cold storage systems are a combination of both and offer several compartments for different temperature settings. Such systems are very useful for companies that deal in mixed products such as meat, dairy, and vaccines or need them for e-commerce deliveries.

Relevance of Different Sectors

In the agricultural sector, cold storage plays a pivotal role in minimizing post-harvest losses. Some of the leading states that have pioneered the use of climate-controlled storage facilities are Maharashtra for grapes, Himachal Pradesh for apples, and Punjab for potatoes. Meanwhile, the seafood and meat sectors rely on freezing equipment for quality control and to reduce spoilage-related losses. In the pharmaceutical industry, the storage of vaccines, APIs, and biologics requires facilities with proprietary temperature controls, which are increasingly being used. E-commerce and grocery stores also require cold storage for the final logistical steps in densely populated metros like Delhi, Mumbai, and Bengaluru.

Related: Cold Chain Project Opportunities

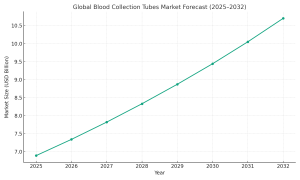

Market Size and Forecast

The cold storage market in India is estimated at ? 715 billion and projected to reach ? 1,500 billion by 2027, growing at a CAGR of 14.8%. Increased consumption of perishables, organized retail expansion, and a greater focus on exports in the pharmaceutical and seafood sectors are driving this growth. Additionally, infrastructure aid like the PM Kisan SAMPADA Yojana is improving access to subsidies, making cold storage a pragmatic investment for small and mid-size entrepreneurs.

Choosing The Right Location

Choosing the correct site for your facility is one of the most important decisions. The site should ideally be close to production or consumption centers, for example, Nashik for grapes, Lucknow for potatoes, and Kochi for seafood. Along with saving on transportation costs, this will reduce operational costs too. The presence of uninterrupted power, water, and other utilities, along with weather conditions and the availability of skillful labor, also impacts the long-term prospects of cold storage.

Designing and Building Your Facility

An ideal cold storage structure incorporates insulated PUF panels and can be based on pre-engineered building (PEB) models, which allow for quicker and cheaper construction. Depending on the scale, refrigeration systems can be either ammonia-based for industrial-sized facilities or Freon-based for smaller operations. Each temperature zone within the facility is meant to store goods within a plus or minus range. For instance, +5°C for dairy and fruits, and 18°C or lower for seafood and certain meats. Along with these, the facility should also have automated door systems, proper drainage, and humidity control to maintain product safety and quality.

Technology and Automation

Today’s cold storage facilities incorporate modern technologies like IoT sensors for real-time monitoring of temperature and humidity, automated compressors for efficient power usage, and backup power systems like diesel generators and solar panels. Management, control, and metering systems for energy management can considerably lower electricity expenses, which is a major expense for such facilities. Integrated systems for inventory, billing, and customer interactions boost service levels and help manage large-scale cold storage operations seamlessly.

Operations and Human Resources

Managing a cold storage facility requires trained personnel who specialize in handling perishables, refrigeration systems, and sanitation. Daily inventory management, scheduled preventive maintenance, quality-control checks, and safety drills showcase rigorous operational discipline. Staff trained in HACCP, ISO, or WHO-GMP standards, especially in food and pharma, improves compliance and company reputation. Operators are able to provide additional services such as re-packaging and labeling, which help diversify the customer base and increase margins.

Cold Storage Categorized by Use Case

Businesses usually sort their cold storage by different commodities. Multi-commodity storages deal with multiple goods together, servicing different seasons and customer segments and catering to different seasons and customer segments. Pharma cold rooms have to follow strict WHO-GMP guidelines, making them sterile with all surveillance done in real time, and with continuous temperature checking.

Licensing and Legal Regulations

Cold storage units that deal with food have to register with the Food Safety and Standards Authority of India (FSSAI), making them legally able to store food. Some of the refrigerants like ammonia or Freon may need some clearances from the Pollution Control Board. For fire safety, the NOCs, electrical safety certificates, and building permits are all mandatory. For pharmaceutical cold storage, licenses from the Drug Control Authority are mandatory. Compliance to the labor laws and regular audits on hygiene also help with client trust.

Ideal Places for Setting Up Cold Storage Facilities

Some regions in India prove to be more beneficial than others in terms of the flow of commodities, the industrial clusters, and even the location of the facilities. Nashik’s grape exports and Visakhapatnam’s seafood are important for these cold storage sectors. In terms of pharmaceutical cold rooms, Baddi in Himachal and Hyderabad in Telangana are very strong synergistic regions. Moreover, cold storage hubs in Delhi, Mumbai, and other cities serve the booming e-commerce logistics industry. Facilities that are located in SEZs or food parks receive additional benefits in terms of government incentives and ease of compliance.

For more information, check out the video on the cold storage business

How NPCS Assists in Your Cold Storage Venture

NPCS aids cold storage entrepreneurs by preparing market surveys and techno-economic feasibility reports for the cold storage projects. These reports cover extensive market surveys, including product and raw material listing, plant layout, utility planning, and regulatory checklists. NPCS covers the entire supply chain along with the technology needed for the business, making the operations smooth and sustainable.

Find Best Idea for Yourself With our Startup Selector Tool

Final Takeaway: Why Cold Storage is a Resilient Evergreen Business

One of the few businesses to combine reliable recurring revenue, real estate value increase, and exceptional customer loyalty, meaningful impact, and meaningful impact is cold storage. It supports farmers, reduces food inflation, enables safer healthcare, and empowers exports. It helps with exports. Entrepreneurs willing to invest in intelligent automation, sustainable design, and strategic location will not only be able to turn a profit, but will also greatly impact India’s cold chain infrastructure in the coming decade, redesigning India’s cold chain landscape in the coming decade.